The Kleemann Kompressor System for the M159 V8 engine is similar to our M156 Kompressor System, but different in many ways as well. The configuration of the M197 chassis allows for a different layout of the Kompressor and its intercooler, allowing for much larger plenum volumes, significantly larger intercooler, and less complex intake system.

Machined from billet aluminum, each part from the smallest pulley to the largest plenum chamber is master crafted on state of the art CNC machines to ensure the highest quality, fit and finish. Keeping with Motorsport tradition, all joining parts of the inlet system and intercooler employ captive O-Rings rather than gaskets and sealants for consistent sealing and maximum reliability. Every finished unit is hand inspected, pressure tested (both the manifold and intercooler systems) and scrutinized for quality before it’s allowed to leave our production facility. We have again turned to Magnuson for their TVS2300 positive displacement supercharger, for many reasons. Unlike screw-type superchargers, which compress air internally leading to an increase in both discharge temperatures and parasitic drive loss, the TVS2300 maintains consistently low discharge temperatures and drive losses across it’s operating range. A large, internal bypass valve is employed to ensure smooth throttle transitions and to keep parasitic drive losses to a minimum. Like our M113 supercharger, we again choose to integrate an air-to-water intercooler within the intake manifold to maintain a very clean installation and maximum efficiency.

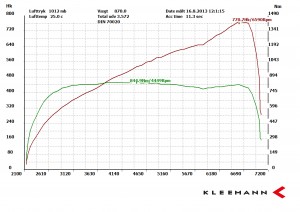

We have used our extensive knowledge and experience with supercharging Mercedes-Benz V8 engines to create a supercharger kit that’s easy to install, and capable of producing very large power gains on the M156 63 engine. The supercharger develops 0.6 BAR (8PSI) resulting in huge power increases of up to 275 HP and 338 NM (250 lb/ft.) depending on the engine variant and additional tuning components installed.

For more, please check M159 Engine